CMM Engineer: An Essential Role in Quality Assurance

Explore the role of a CMM Engineer, their responsibilities, career path, required skills, and salary insights in India and the US.

What is a CMM Engineer?

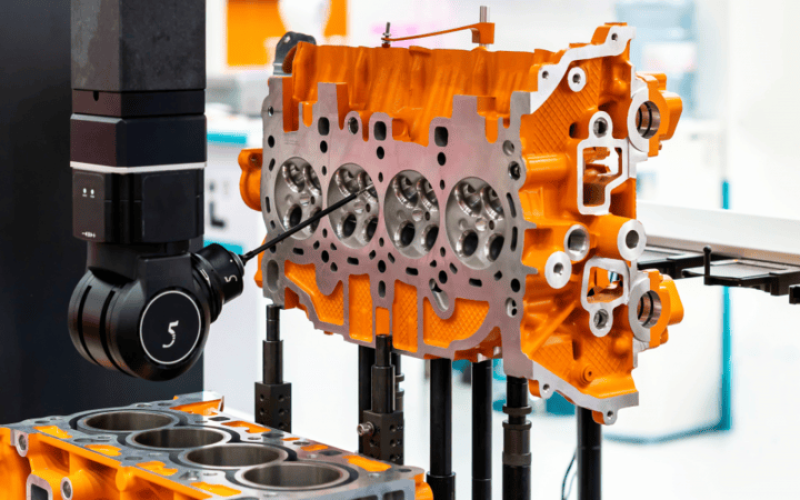

A CMM Engineer (Coordinate Measuring Machine Engineer) specializes in operating and programming CMMs to inspect, measure, and validate the dimensional accuracy of manufactured components. These engineers ensure that products meet precise specifications, playing a critical role in industries like automotive, aerospace, defense, and manufacturing. Their expertise ensures high-quality products and adherence to stringent industry standards.

How to Become a CMM Engineer

Educational Qualifications:

- A degree in Mechanical Engineering, Manufacturing Engineering, or a related field.

- Diploma holders in mechanical or production engineering can also enter this field.

Skill Development:

- Programming Skills: Proficiency in software such as PC-DMIS, Calypso, or QUINDOS.

- Metrology Knowledge: Understanding of geometric dimensioning and tolerancing (GD&T).

- Hands-On Experience: Training on operating and programming CMMs.

Certifications:

- Metrology-related certifications such as ASME Y14.5 or equivalent.

- Specialized CMM programming training from certified institutions.

Experience:

- Entry-level roles in quality assurance or inspection.

- On-the-job training to gain expertise in advanced CMM programming and operations.

Continuous Learning:

- Stay updated with the latest technologies in metrology and advanced measurement systems.

Roles and Responsibilities of a CMM Engineer

CMM Programming and Operation:

- Create and modify CMM programs to inspect components based on engineering drawings.

- Operate CMMs to measure dimensions, tolerances, and geometric parameters.

Inspection and Validation:

- Perform dimensional analysis and ensure products meet design specifications.

- Validate components and assemblies during production.

Report Generation:

- Document inspection results and generate detailed reports for stakeholders.

- Analyze deviations and recommend corrective actions.

Maintenance and Calibration:

- Ensure the CMM is properly maintained and calibrated for accurate measurements.

- Troubleshoot issues related to machine performance.

Collaboration:

- Work closely with design, production, and quality teams to address issues and improve processes.

- Provide feedback on design feasibility and manufacturability.

Compliance:

- Ensure adherence to industry standards, such as ISO 9001, AS9100, or IATF 16949.

CMM Engineer Salary

Salaries for CMM Engineers depend on factors like location, industry, experience, and technical expertise.

India:

- Entry-level: ₹3,50,000–₹5,00,000 per annum.

- Experienced: ₹6,00,000–₹10,00,000 per annum.

United States:

- Entry-level: $50,000–$70,000 per annum.

- Experienced: $80,000–$100,000 per annum.

Why is a CMM Engineer Important?

The role of a CMM Engineer is vital in ensuring product quality and compliance with strict industry standards. By leveraging their skills in metrology and programming, they help prevent costly production errors, maintain customer satisfaction, and uphold a company’s reputation for excellence.

Conclusion

A career as a CMM Engineer offers a blend of technical expertise, problem-solving, and precision. With a growing demand for quality assurance in manufacturing, CMM Engineers are critical to ensuring that products meet exacting standards. For individuals passionate about metrology and quality, this role provides an excellent pathway for growth and innovation in high-tech industries.

Keywords:

CMM Engineer, Coordinate Measuring Machine Engineer, CMM programming, CMM operation, metrology, quality assurance, GD&T, CMM Engineer salary, CMM programming training, PC-DMIS, Calypso, dimensional inspection, manufacturing quality, CMM calibration, CMM Engineer India, CMM Engineer US.

Write A Comment

No Comments